48 Special

Models owner

Thorsten Schrecke has a 30 years expierence as a modelmaker and is in

first

a film effects specialist. As a modelmaker the studied

animationdirector

has worked on a lot of movie projects, such as Independence Day. His

privat

interests are also the aircrafts of WWII and especially the exotic

ones.

So what is more natural than opening his own modelkitlabel, for all who

share his passion.

The

DFS-346 was one of his privat favorits and that is why it became the

first

kit of the newly formed label.

History of

Development

The

DFS-346 was a middle winged full metal construction and was under

developement at the end of the war in the Siebel Werke in Halle at the

Saale (Saxony). The plane was designed for high speed sonic and

supersonic

and high altitude testflights. Due to problems faced by German

engineers

while designing the new jet airplanes, the construction of a scientific

airframe was decided.

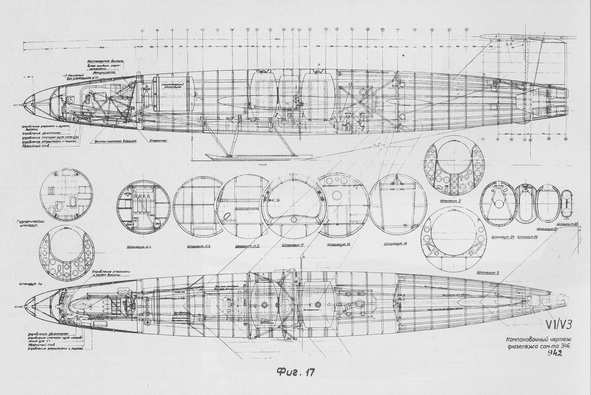

Original

drawing of the russian V1/V3 Version with sharp angled elevator (not

used).

Picture

via Helmut Walther

The

end of war prevented the finishing and testing of the DFS-346

called

testplane. The red army captured the plane and sent it to the USSR. The

in development involved engineers got the offer to continue their work

in the USSR. Facing the alternatives the engineers took the offer.

Almost

like in the "Operation Paperclip", when German rocket scientists around

Werner von Braun moved to the USA, it happended to the DFS-346

aircraftspecialists.

They were moved, with families and households to a small village

called Podbersje near by Dubna. Here two construction offices

(OKB-1

& OKB-2) were established. OKB –1 was headed by Brunolf Baade

and OKB-2 by Hans Rössing. Although the accommodation

had nothing to do with a prison or one of the feared camps, the Germans

were watched carefully. There was no doubt that the Russians only

wanted

their knowledge and didn't let them get new scientiffic results. This

proofs

the fact of P.N. Obrudow and A.J. Beresnjak beeing established as

deputizing heads of the construction offices.

At

the beginning of the work in 1946 the DFS-346 produced in Germany was

checked

out careful at the ZAGI-windtunnel T-101. From its shape was built a

more

advanced, longer version of the DFS-346. It was still called 346.

The

front fuselage of the 346 is a rotationbody based on the NACA-Prifile

0,0121-0,66-50.

The middle part was cylindric and narrowed to the square diametre of

the

back. Presumingly for capacity and weight reasons the DFS-346 was

equipped

already in Germany with one of the loved landing skids. It was kept

later

on too and caused trouble several times. The wings were 45°

swept-back

and got 25% average depth and a NACA- 0,012-0,55-1,25 profile with 12%

relative thickness. The area measured 19,87m2.

The completely continueing profile shape caused a stall in

certain

flight positions, which caused complete loss of control. This was

stopped

by use of fences on the top of the wings.

It

was motorized with a German built two chaimber liquid rocket engine

Walter

HWK 109-509, which was renamed ShRD 109-510 in the USSR. It had

36.7

kN of thrust on the ground and 39.2 kN of thrust in operational hight.

The DFS-346 could carry 1900 kg of fuel. It consited of hydrazinhydrant

with methlyalcohol and water. The oxidizer was 82% Hydrogenperoxyd.

The

pilot was lying on a plank bed in a pressureized cabine, which also

worked

as an emergency system. This kind of position was very uncomftable for

the pilot and in certain flight situations almost dangerous. It was

chosen

for aerodynamic reasons.

The

emergency system was very progressiv and worked, in opposit to the X-2,

perfect. The cabine was seperated from the fuselage by four explosive

bolts.

A dragchute placed in the backwall of the cabine stabilized the

cockpit.

In an safe altitude the plank bed including the glass dome was

catapulted

off the cabine. Another chute stabilized the flight and drew the pilot

off the plank. Then the pilots parachute opened and returned him safely

to the ground.

This

operation worked automaticly and was tested several times successfully.

Therefore a cockpitsection was lifted on altitude by a B-25J and

dropped.

The system saved the live of German testpilot Wolfgang Ziese on

14.

September 1951, when the aircraft went off control in 7000 m on a

rocketed

flight.

The

DFS-346 was built in several versions. The DFS-346-1 and DFS-346-3

where

used for flighttests.The DFS-346-P was a gliderversion without engines.

What happend to the surely built DFS-346-2 is unknown. The aircraft

differ

very little in design. Only elevator and rudder showed differences in

construction.

All

aircraft where lifted to altitude by a carrier aircraft and droped.

Therefore

an original B-29 , which had had an emergency landing in the pacific

territory

was used. Some say there were also a JU-388 and a TU-4 in use. But

there

are no photographs of it.